Schaublin 125-CNC retrofit.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

16 Dec 2022 07:56 #259614

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 138

16 Dec 2022 14:27 - 16 Dec 2022 14:43 #259639

by smc.collins

Replied by smc.collins on topic Schaublin 125-CNC retrofit.

linuxcnc calculates vout from voltage and velocity

if you have 3m/m in your ini over a 10v span, than you need to make sure the drive gives 3m/m over the same span.

that is why you have the gain error. yes my math was backwards, I've been busy trying to solve a different issue.and my brain crossed some wires.

so let me illustrate your gain issue.

of you send a command of 3v, do you get 1m/m ?

if you send 6v do you get 2m/m

lets say the machine could go say 5m/min

same thing

you voltage scaling to velocity is effected by you values in your ini. afaict, your drives are runnig below the requested velocity as it stands. So you can lower you total max velocty setting this in the ini, or increase the drives total velocity to match.

the other possibility, with your current overshoot, is that your declared acceleration rate in your ini is higher than what the drive can achieve.

can you zoom that scop output more ??

if you have 3m/m in your ini over a 10v span, than you need to make sure the drive gives 3m/m over the same span.

that is why you have the gain error. yes my math was backwards, I've been busy trying to solve a different issue.and my brain crossed some wires.

so let me illustrate your gain issue.

of you send a command of 3v, do you get 1m/m ?

if you send 6v do you get 2m/m

lets say the machine could go say 5m/min

same thing

you voltage scaling to velocity is effected by you values in your ini. afaict, your drives are runnig below the requested velocity as it stands. So you can lower you total max velocty setting this in the ini, or increase the drives total velocity to match.

the other possibility, with your current overshoot, is that your declared acceleration rate in your ini is higher than what the drive can achieve.

can you zoom that scop output more ??

Last edit: 16 Dec 2022 14:43 by smc.collins.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

16 Dec 2022 14:45 - 16 Dec 2022 14:49 #259640

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

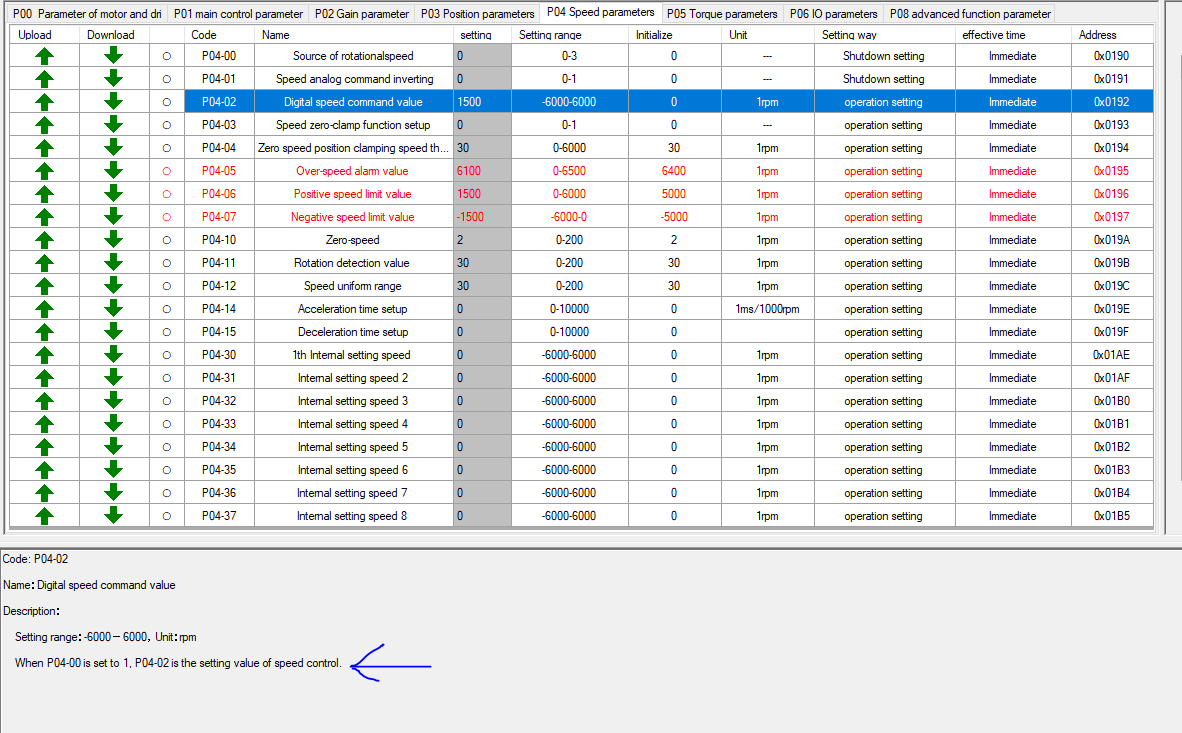

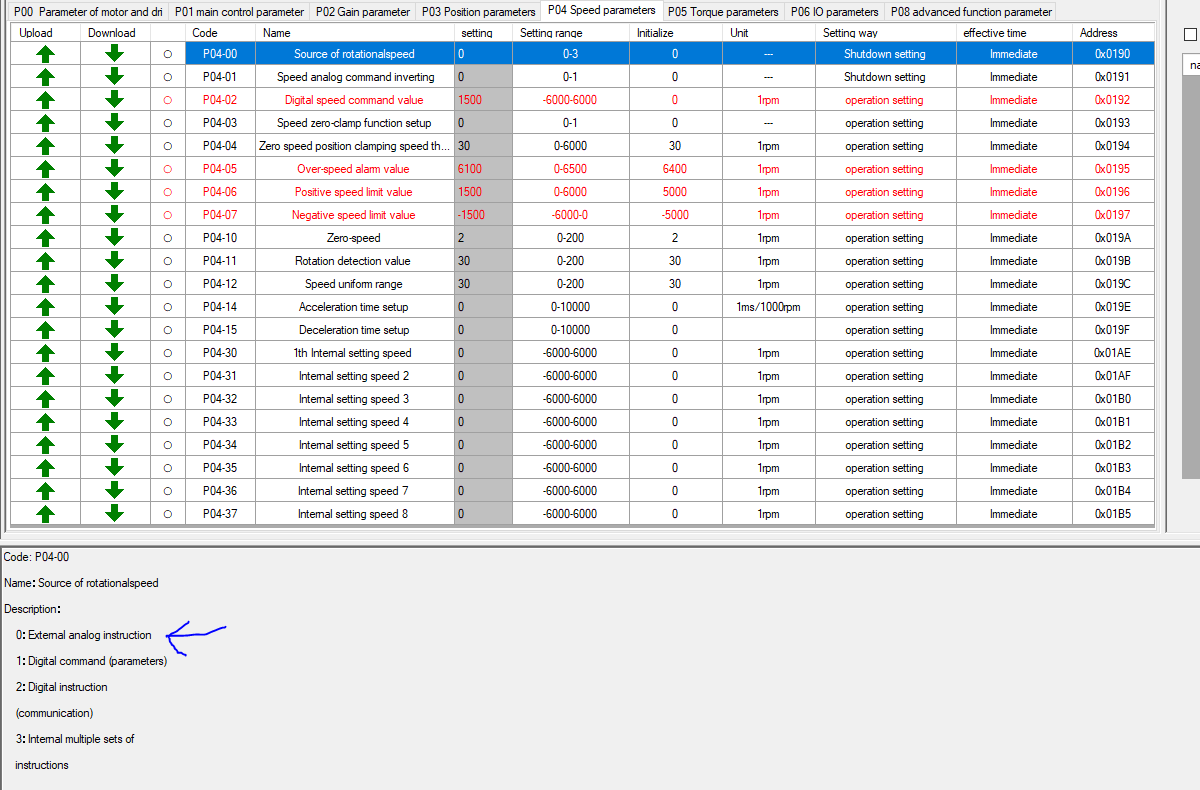

Oh, I think I am slowly understanding. (Thanks for your patience).

Since I want the axis to run a max of 3m/min, I should change the digital motor speed command value in the driver P04-02 down from 3000rpm, to 1500rpm, so that a 10V max speed command from LinuxCNC will result in that 1500 RPM being commanded by the driver, rather than the driver running the motor up to 3000rpm, and and getting told to slow down by LCNC.

Since I want the axis to run a max of 3m/min, I should change the digital motor speed command value in the driver P04-02 down from 3000rpm, to 1500rpm, so that a 10V max speed command from LinuxCNC will result in that 1500 RPM being commanded by the driver, rather than the driver running the motor up to 3000rpm, and and getting told to slow down by LCNC.

Last edit: 16 Dec 2022 14:49 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

16 Dec 2022 17:09 - 16 Dec 2022 17:12 #259655

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

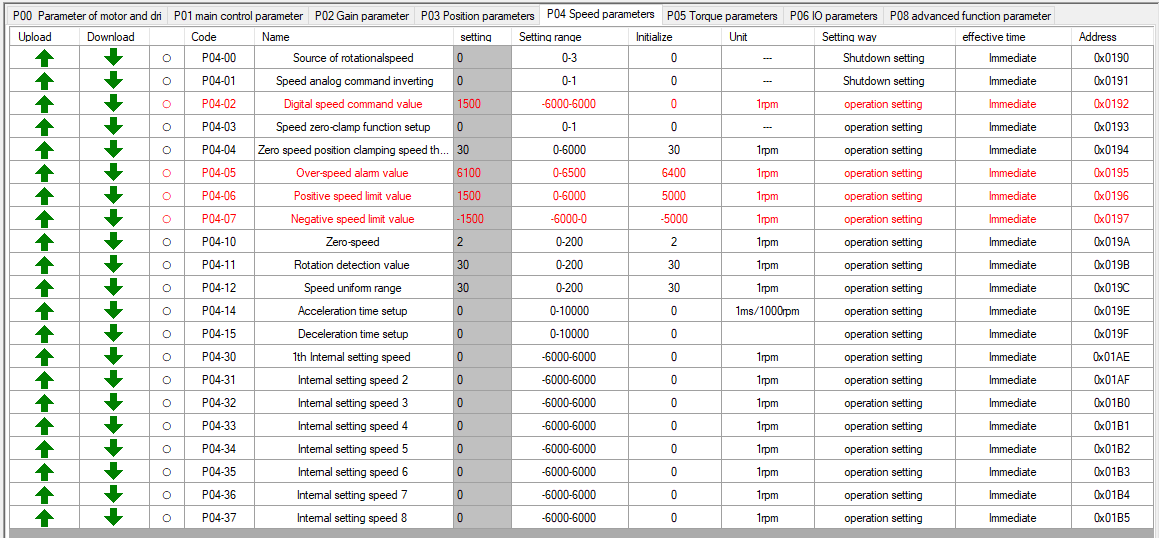

I left P00-03 MOTOR RATED SPEED = 3000,

but changed the following:

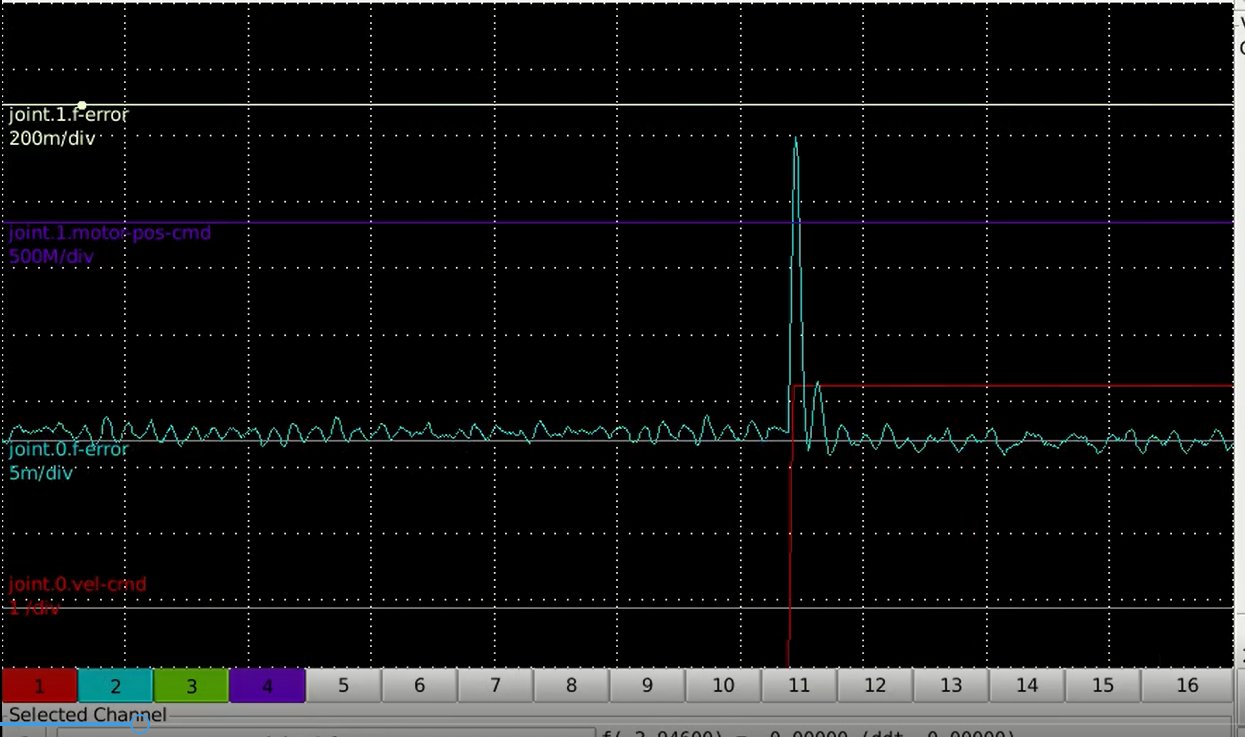

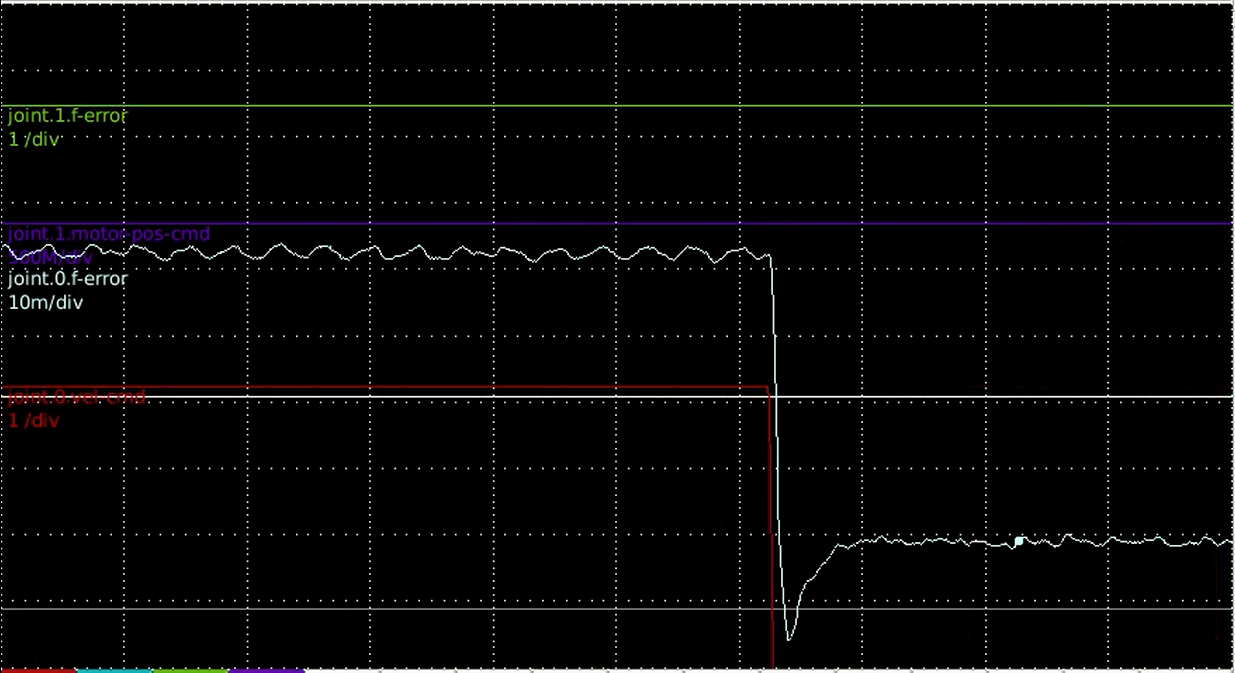

This is the resulting plot with the same P 15, FF0.1 as yesterday. This is the motion reversal with a slow feedrate of 200 mm/min.

EDIT: I just noticed that I doubled the sensitivity. The change made no significant difference yet. The motor is not ringing at idle.

Cheers,

Mark

but changed the following:

This is the resulting plot with the same P 15, FF0.1 as yesterday. This is the motion reversal with a slow feedrate of 200 mm/min.

EDIT: I just noticed that I doubled the sensitivity. The change made no significant difference yet. The motor is not ringing at idle.

Cheers,

Mark

Attachments:

Last edit: 16 Dec 2022 17:12 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

16 Dec 2022 17:16 - 16 Dec 2022 18:01 #259656

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Attachments:

Last edit: 16 Dec 2022 18:01 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

16 Dec 2022 17:27 #259657

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

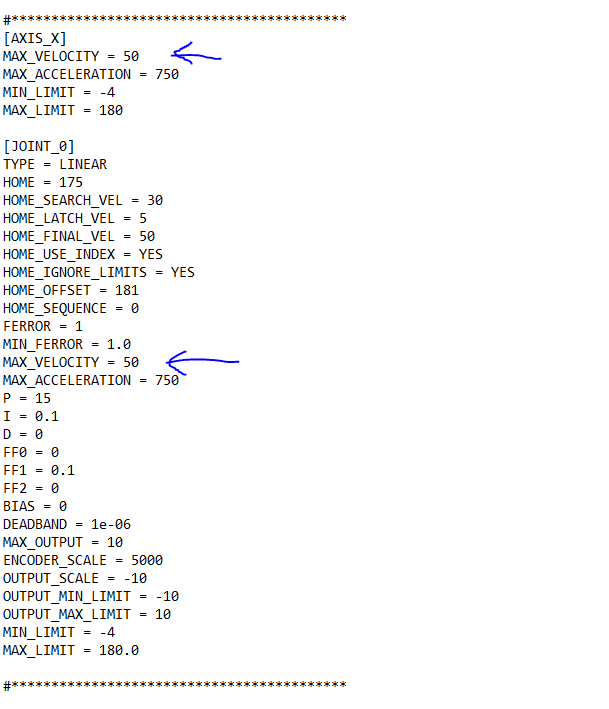

Is this the reason for the separate (to me seemingly redundant) max speed settings in the INI, for both axis and Joint?

Am I supposed to set the Joint to match the driver (MAX Velocity 100 --> 10V --> 3000RPM motor rated speed), and then just limiting it to the desired half that, by setting the X Axis max speed to 50?

Mark

Am I supposed to set the Joint to match the driver (MAX Velocity 100 --> 10V --> 3000RPM motor rated speed), and then just limiting it to the desired half that, by setting the X Axis max speed to 50?

Mark

Attachments:

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

16 Dec 2022 17:56 - 16 Dec 2022 17:59 #259659

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Attachments:

Last edit: 16 Dec 2022 17:59 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

16 Dec 2022 19:33 - 16 Dec 2022 19:48 #259664

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

...a few hours later...

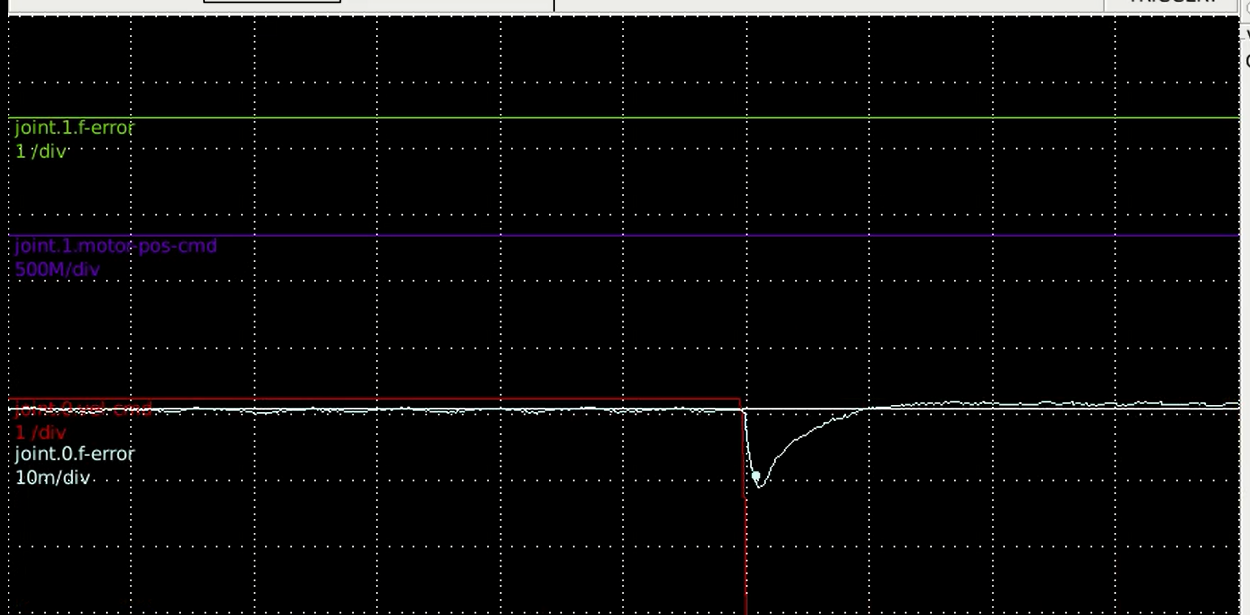

I ran up the drivers auto tune till I got resonance (at 21). Backed it off, first to 20, and then after more testing to 19.

The best tuning I came up with so far on X is the drive auto tuned at 19, Linuxcnc P15, FF 0.2.

Next angle of attack is to look whether I have the Accel too high.

I ran up the drivers auto tune till I got resonance (at 21). Backed it off, first to 20, and then after more testing to 19.

The best tuning I came up with so far on X is the drive auto tuned at 19, Linuxcnc P15, FF 0.2.

Next angle of attack is to look whether I have the Accel too high.

Attachments:

Last edit: 16 Dec 2022 19:48 by RotarySMP.

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 138

16 Dec 2022 19:59 - 16 Dec 2022 20:03 #259667

by smc.collins

Replied by smc.collins on topic Schaublin 125-CNC retrofit.

yes, you got it. I wasn't sure if your servo was geared down or up from your lead screw. so yes, you need to tune your velocity for your lead screw pitch. Linux CNC calculates your velocity from pulse count versus travel distance.

Motor velocity & gear ratio = actual velocity with lead screw pitch etc accounted for.

Most of my tuning has been with brush dc motors, they have a lot more grunt on acceleration at low speed. If you have extra servo speed, maybe increasing giving the servo motor to lead screw more ratio would help if you can't get reasonable acceleration response. More TQ at the lead screw, More HP at the motor. did this lathe originally have DC servos ?

as to yor prior question.

Yes your drive velocity total travel needs to match in the drive and linux CNC.

For instance

If the drive has to run the motor at say 10,000rpm to go 10,000mm/sec, then your ini value is 10,000mm/sec

you need to account for ALL of the gearing and pulse counts. definitely looks like the acceleration rate is to high, by about 100%. try cutting it in half.

MAX_Accle is currently 750, make is 375, see if that helps

Motor velocity & gear ratio = actual velocity with lead screw pitch etc accounted for.

Most of my tuning has been with brush dc motors, they have a lot more grunt on acceleration at low speed. If you have extra servo speed, maybe increasing giving the servo motor to lead screw more ratio would help if you can't get reasonable acceleration response. More TQ at the lead screw, More HP at the motor. did this lathe originally have DC servos ?

as to yor prior question.

Yes your drive velocity total travel needs to match in the drive and linux CNC.

For instance

If the drive has to run the motor at say 10,000rpm to go 10,000mm/sec, then your ini value is 10,000mm/sec

you need to account for ALL of the gearing and pulse counts. definitely looks like the acceleration rate is to high, by about 100%. try cutting it in half.

MAX_Accle is currently 750, make is 375, see if that helps

Last edit: 16 Dec 2022 20:03 by smc.collins.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1542

- Thank you received: 572

16 Dec 2022 20:07 #259669

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

The X axis has very little mass. I dont need exceptionally dynamic performance from a lathe, so I wont be changing the gearing. I'll revist the accel, and see if I can get rid of that bump. The Z is already geared down more than X.

The original motors were DC servo's, but I did the MoI and Torque calcs on these AC Servos with the drive train and loads, and should be in the 1:1 - 1:2 inertial coupling range, with plenty of excess torque, so I should be able to find a sweet spot.

Sorry it took so long to get that gain setting understood. It is pretty obvious once I got it. Duh!

Would you tend to spend a lot of time trying to manually tune the drive, or just back off a bit from the edge of autotunes performance limit, and then do the rest in LCNC?

The original motors were DC servo's, but I did the MoI and Torque calcs on these AC Servos with the drive train and loads, and should be in the 1:1 - 1:2 inertial coupling range, with plenty of excess torque, so I should be able to find a sweet spot.

Sorry it took so long to get that gain setting understood. It is pretty obvious once I got it. Duh!

Would you tend to spend a lot of time trying to manually tune the drive, or just back off a bit from the edge of autotunes performance limit, and then do the rest in LCNC?

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.457 seconds