Schaublin 125-CNC retrofit.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 138

16 Dec 2022 20:39 - 16 Dec 2022 20:42 #259673

by smc.collins

Replied by smc.collins on topic Schaublin 125-CNC retrofit.

I'd remove all the lcnc pid authority, tune the drive and ini values to get tight control, then watch lcnc while it works and maybe touch P and ff1 as needed for edge cases. basically get really good open loop control first. i do this with engines to.

find what makes the engine happiest, then bring the AF sensor feedback values to that. don't tune to make the AF happy, make the cylinder happy. same deal here.

i might be misreading the ff error, maybe accel needs to be 1500 instead of 750.

yeah those servos are 220v 3phase 2.8 amps ?? so 700watt ish, that's a lot.

but now you know how to get to say 6500mm/min with good control.

you got this now Mark,

find what makes the engine happiest, then bring the AF sensor feedback values to that. don't tune to make the AF happy, make the cylinder happy. same deal here.

i might be misreading the ff error, maybe accel needs to be 1500 instead of 750.

yeah those servos are 220v 3phase 2.8 amps ?? so 700watt ish, that's a lot.

but now you know how to get to say 6500mm/min with good control.

you got this now Mark,

Last edit: 16 Dec 2022 20:42 by smc.collins.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1539

- Thank you received: 571

17 Dec 2022 10:45 - 17 Dec 2022 10:47 #259723

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

"I'd remove all the lcnc pid authority, tune the drive and ini values to get tight control,"

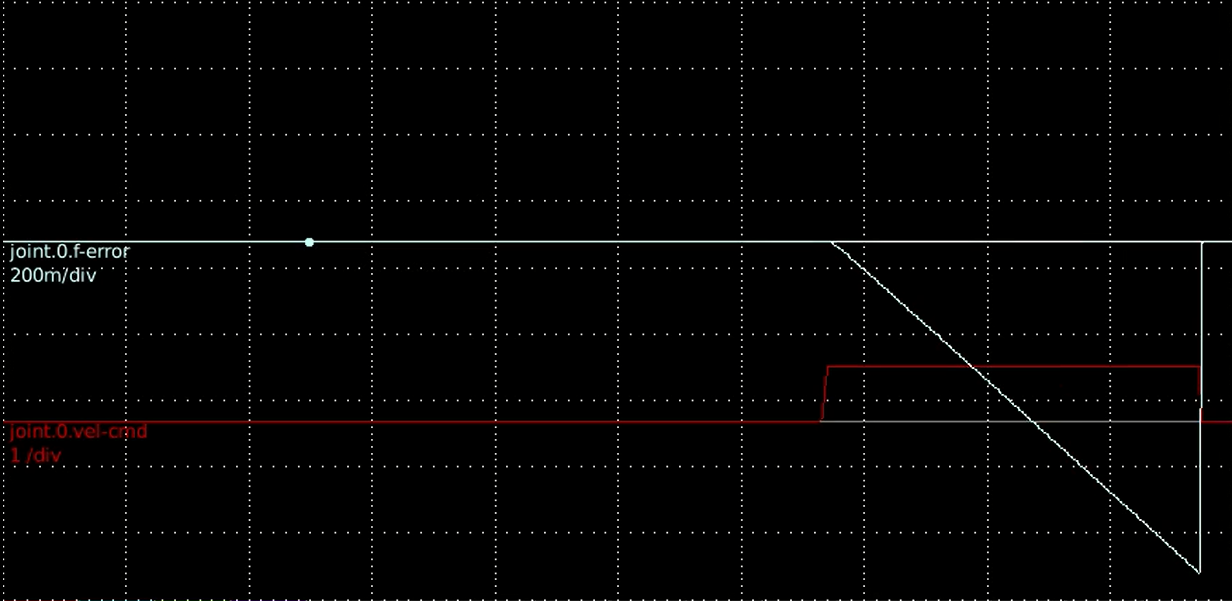

I halved the accel, and set LCNC to open loop (P0 FF1), and did a 0.25mm feedrate move at 50mm/min. This still creates a following error. Current INI settings are FERROR =1 and MIN_FERROR= 1 on this axis.

Why would I trip a following error, every time, with a slow 0.25mm move if MIN_FERROR = 1?

Once everything is tuned, What would be a normall FERROR allowance for a pretty slow, but hopfully quite precise machine like this? 0.01 Min and 0.025 at speed?

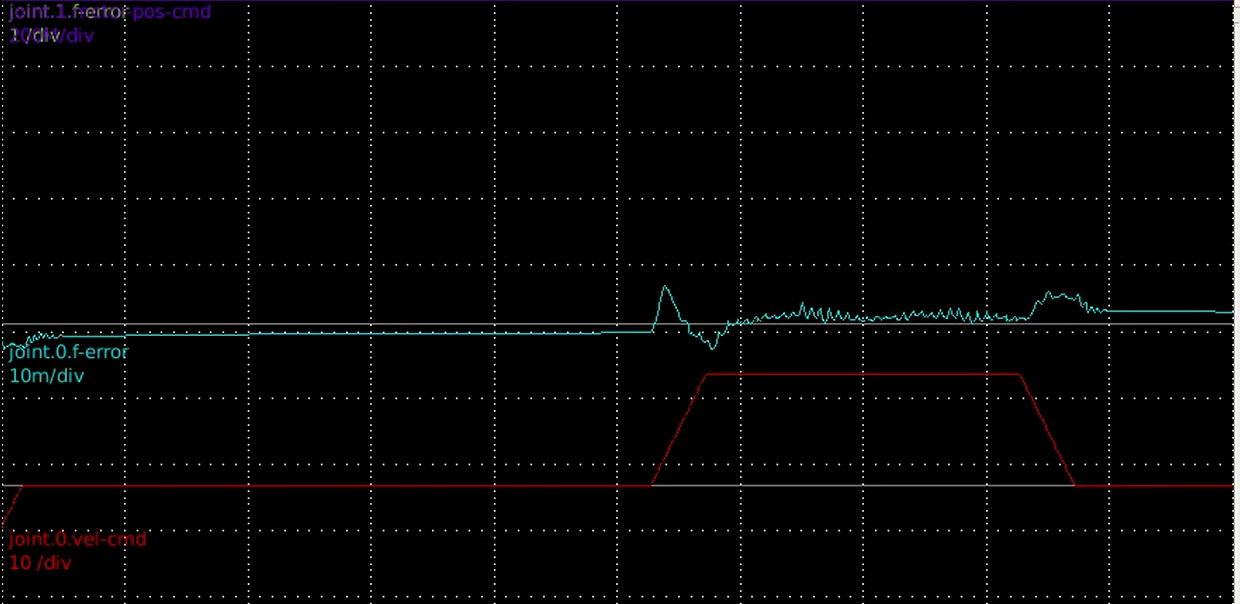

This is the plot.

I halved the accel, and set LCNC to open loop (P0 FF1), and did a 0.25mm feedrate move at 50mm/min. This still creates a following error. Current INI settings are FERROR =1 and MIN_FERROR= 1 on this axis.

Why would I trip a following error, every time, with a slow 0.25mm move if MIN_FERROR = 1?

Once everything is tuned, What would be a normall FERROR allowance for a pretty slow, but hopfully quite precise machine like this? 0.01 Min and 0.025 at speed?

This is the plot.

Attachments:

Last edit: 17 Dec 2022 10:47 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1539

- Thank you received: 571

17 Dec 2022 14:38 #259730

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

I really cnt see any better way of tuning the drive than using it's "autotune" settings (which are just a look up table of discrete configurations). With LinuxCNC in openloop mode, and doing short jogs within the FERROR, I cant do better with the LinuxCNC Osci, than I can get by just increasing the auto tune to instablity and then backing off.

Having done that, I then used Tommy's tuning instructions once again.

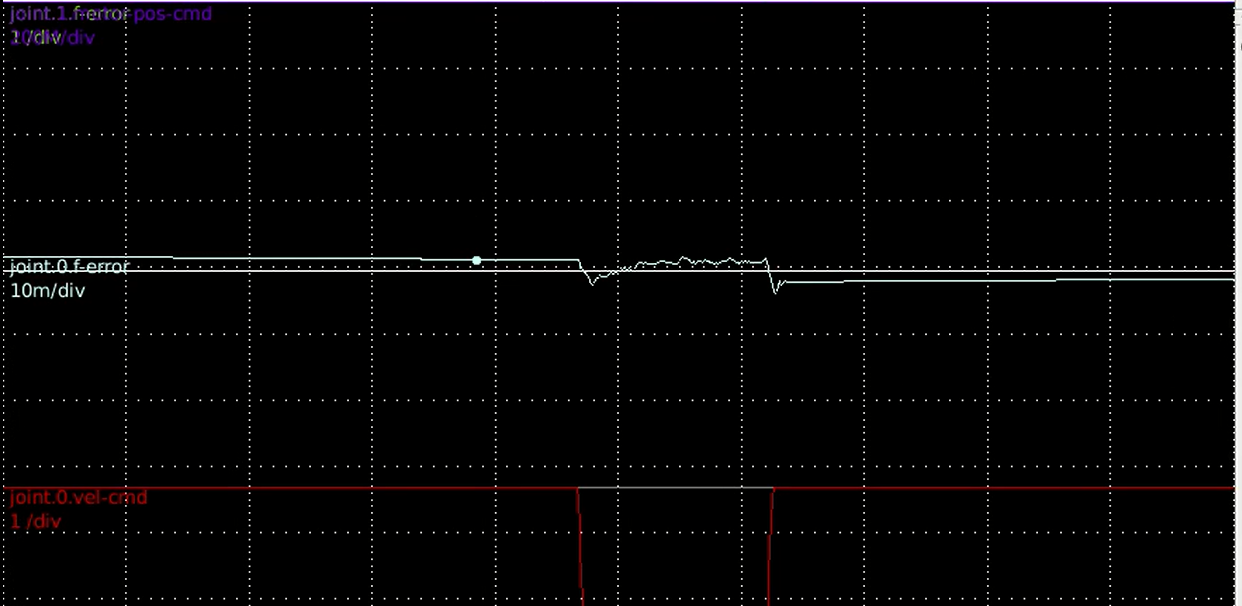

At 200mm/min this is the best I can get tuned.

At 500mm/min :

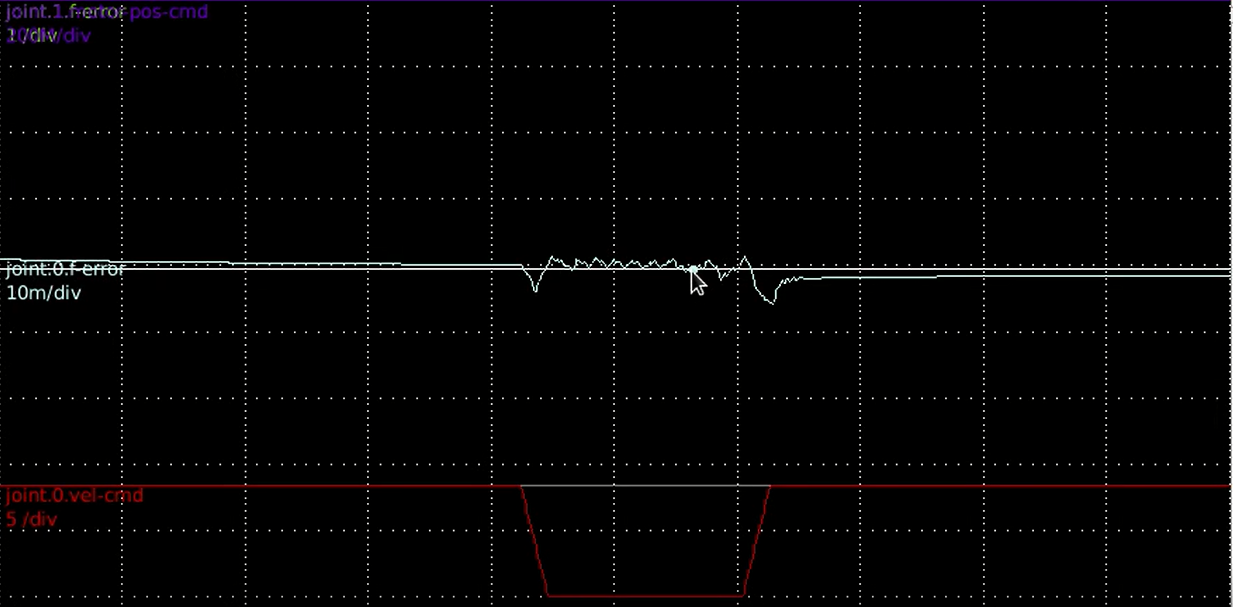

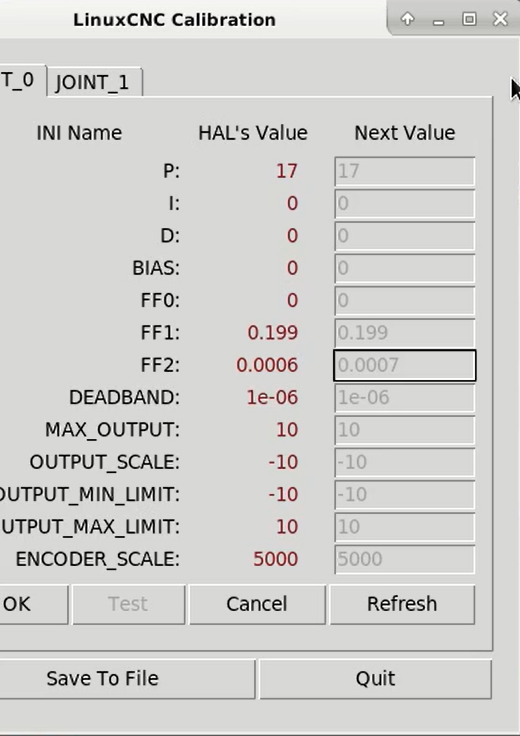

And these are the best settings I came up with and the plot at 1000mm/min

What are your thoughts on this? How anal do I need to go on this. You can keep zooming and zooming, and can always have it looking terrible.

I rewatched Peter (Talla83) excellent video, where he just used a vise as a crute linear way, and he seems to have only stayed at 1/Div, whereas I am used 10m/Div. At 1/div, my plot is a flat line.

Having done that, I then used Tommy's tuning instructions once again.

At 200mm/min this is the best I can get tuned.

At 500mm/min :

And these are the best settings I came up with and the plot at 1000mm/min

What are your thoughts on this? How anal do I need to go on this. You can keep zooming and zooming, and can always have it looking terrible.

I rewatched Peter (Talla83) excellent video, where he just used a vise as a crute linear way, and he seems to have only stayed at 1/Div, whereas I am used 10m/Div. At 1/div, my plot is a flat line.

Attachments:

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 138

17 Dec 2022 16:23 #259737

by smc.collins

Replied by smc.collins on topic Schaublin 125-CNC retrofit.

well, i think you're just about there. my only suggestion is to start moving faster and see if the amplitude is small or not.

have you calculated out the variables fpr the servo control and drive ??

max motor rpm = x velocity mm/sec

made sure that is what your ini file reflects this

that your max input voltage to the drive is 10v in ini and drive

max velocity etc.

adjust the acceleration rate in the ini to reflect the physical ability of the

mechanical assembly

if all that is good and co-ordinated, then yes it's time to work with the lcnc pid.

if your total max velocity is 3m/min

I'd test at 1m/min 2m/min 3m/min

if everything looks good. yeah, that's when it's time to get after the pid adjustments. my suspicion is that your drive input gain settings might be to low, but, see what ya get.

have you calculated out the variables fpr the servo control and drive ??

max motor rpm = x velocity mm/sec

made sure that is what your ini file reflects this

that your max input voltage to the drive is 10v in ini and drive

max velocity etc.

adjust the acceleration rate in the ini to reflect the physical ability of the

mechanical assembly

if all that is good and co-ordinated, then yes it's time to work with the lcnc pid.

if your total max velocity is 3m/min

I'd test at 1m/min 2m/min 3m/min

if everything looks good. yeah, that's when it's time to get after the pid adjustments. my suspicion is that your drive input gain settings might be to low, but, see what ya get.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21154

- Thank you received: 7222

17 Dec 2022 17:37 #259746

by tommylight

Replied by tommylight on topic Schaublin 125-CNC retrofit.

At 10m/div that looks really good.

Try faster.

Try faster.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1539

- Thank you received: 571

17 Dec 2022 17:47 #259749

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Thanks for the sanity check. It is difficult to work out when you stopped improving the tune, and are just chasing your tail.

I am pretty happy with X now. It sounds #right" all the way up to 3m/min. But then I put the micron clock on it, and looked at what happens with 10micron incremental steps. I can really see why industry when to closing the loop with linear scales.

The Z sounds more grumbly. Even when I soften up the drive, and dial back the P. I wonder if I have a mechanical issue in there somewhere?

I am pretty happy with X now. It sounds #right" all the way up to 3m/min. But then I put the micron clock on it, and looked at what happens with 10micron incremental steps. I can really see why industry when to closing the loop with linear scales.

The Z sounds more grumbly. Even when I soften up the drive, and dial back the P. I wonder if I have a mechanical issue in there somewhere?

The following user(s) said Thank You: smc.collins

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1539

- Thank you received: 571

17 Dec 2022 17:57 #259751

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

"have you calculated out the variables fpr the servo control and drive ??

max motor rpm = x velocity mm/sec"

Yes, I have both drives set for 150 RPM / V, so they will max out at 1500RPM.

X 1500 rpm -->1:2 --> 750 rpm screw --> 4mm pitch = 3m/min

Z 1500 rpm --> 1:3 --> 500 rpm screw--> 6mm pitch = 3m/min

My Ini is set for max rapid = 50mm/sec --> 3m/min

Those plots are with the LCNC PID. With the LCNC in open loop, the FError plot is useless, as it is just a divergent graph. In LCNC Open loop, all I could do was keep increasing the drive stiffness with auto tune values till is resonated, then back it off till stable.

max motor rpm = x velocity mm/sec"

Yes, I have both drives set for 150 RPM / V, so they will max out at 1500RPM.

X 1500 rpm -->1:2 --> 750 rpm screw --> 4mm pitch = 3m/min

Z 1500 rpm --> 1:3 --> 500 rpm screw--> 6mm pitch = 3m/min

My Ini is set for max rapid = 50mm/sec --> 3m/min

Those plots are with the LCNC PID. With the LCNC in open loop, the FError plot is useless, as it is just a divergent graph. In LCNC Open loop, all I could do was keep increasing the drive stiffness with auto tune values till is resonated, then back it off till stable.

The following user(s) said Thank You: smc.collins

Please Log in or Create an account to join the conversation.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 717

- Thank you received: 138

17 Dec 2022 19:07 #259758

by smc.collins

Replied by smc.collins on topic Schaublin 125-CNC retrofit.

Looks like you got it covered, are you now getting good motion and tracking all the way up and down your velocity commands ? if so, mission accomplished sir !

Can you post a video of the noise ?

Can you post a video of the noise ?

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1539

- Thank you received: 571

18 Dec 2022 16:01 #259830

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

This is what it sounds like. With a night to sleep over it, it is not bad, it just sounds different.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21154

- Thank you received: 7222

18 Dec 2022 16:07 #259831

by tommylight

Replied by tommylight on topic Schaublin 125-CNC retrofit.

Sounds healthy on both, Z is heavier so more noise, more motor trying to cope with it, etc etc.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.261 seconds