New Project with Mesa 7I96 and THCAD-05

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

06 Jul 2021 01:20 #213813

by phillc54

forum.linuxcnc.org/38-general-linuxcnc-q...-05?start=350#213802

Touchoff in a work coordinate is not necessarily set to zero, it can be any valid coordinate. You normally set the corner of the material to zero, not the corner of the machines work envelope. Home is also not always the corner of the machines work envelope not where the corner of the material is placed.

Replied by phillc54 on topic New Project with Mesa 7I96 and THCAD-05

You may have missed the dit in my last post:I understand that but why the software does not do it as part of the home function. Like the X and Z. Other software will do it like that.

forum.linuxcnc.org/38-general-linuxcnc-q...-05?start=350#213802

Touchoff in a work coordinate is not necessarily set to zero, it can be any valid coordinate. You normally set the corner of the material to zero, not the corner of the machines work envelope. Home is also not always the corner of the machines work envelope not where the corner of the material is placed.

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

06 Jul 2021 01:38 #213815

by acourtjester

Replied by acourtjester on topic New Project with Mesa 7I96 and THCAD-05

I completely agree with the placement of the setting for the material corner as 0.0

when told where it is. That is how I start a cutting routine great for placing odd shaped metal or using metal in the middle of scrapes. Then why have home switches, to me the home is to set an absolute reference whenever the system is turned on. I don't use the G54 (or other offsets) but these need a reference. For those that use jigs and G-code offset they need a reference to start from.

when told where it is. That is how I start a cutting routine great for placing odd shaped metal or using metal in the middle of scrapes. Then why have home switches, to me the home is to set an absolute reference whenever the system is turned on. I don't use the G54 (or other offsets) but these need a reference. For those that use jigs and G-code offset they need a reference to start from.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

06 Jul 2021 01:55 #213816

by phillc54

Replied by phillc54 on topic New Project with Mesa 7I96 and THCAD-05

G54 is the default Work Coordinate System so you do use it by default. That is the one that is set to zero with the X0Y0 button. GCode without any WCS code (G54~G59.3) assumes G54.

Homing and Touch Off are two different beasts but you need to have both done correctly.

For a plasma table, Homing lets the machine know where in the world the torch is and Touch Off lets the torch know where the material is.

Touchoff needs to be done every time you change material unless you are lucky enough to place the new material in exactly the same place as the previous one. Z axis touchoff doesn't really matter to a PlasmaC based config as all Z motion is controlled by the plasmac component.

Homing and Touch Off are two different beasts but you need to have both done correctly.

For a plasma table, Homing lets the machine know where in the world the torch is and Touch Off lets the torch know where the material is.

Touchoff needs to be done every time you change material unless you are lucky enough to place the new material in exactly the same place as the previous one. Z axis touchoff doesn't really matter to a PlasmaC based config as all Z motion is controlled by the plasmac component.

The following user(s) said Thank You: fernandosf

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11737

- Thank you received: 3973

06 Jul 2021 06:42 #213827

by rodw

Often when setting up a new system, this file ends up with some odd values. I found in my early days, I had to delete this file. I suspect this has been changed in your config. But as said, all you need to do is zero that axis and it will be remembered for next time.

I'm not sure how it compares with Mach, but Linuxcnc has an extensive coordinate system which is well documented here

linuxcnc.org/docs/devel/html/gcode/coordinates.html.

This is really designed for a situation where you might have seperate fixtures on a machining centre. I knew somebody who had 4 vices mounted to a big ally plate that he installed in his mill sometimes. So Each vice could be set up with a different coordinate system (eg G54, G55, G56, G57)

With Plasma, we only really need one coordinate system so we use G54. So when we touch off with the GUI buttons to set X0 Y0 we can also do it in the MDI window by typing G54 X0 Y0.

Also note the QTplasmac can rotate the coordinate system around the toch to account for a squewed sheet from the GUI. I'll let you explore that feature in the QTplasmac docs

Replied by rodw on topic New Project with Mesa 7I96 and THCAD-05

Linuxcnc has a memory of all its settings. Its saved in a .var file in your config folder. Plasmac my use a different file extension.I understand that but why the software does not do it as part of the home function. Like the X and Z. Other software will do it like that.

Often when setting up a new system, this file ends up with some odd values. I found in my early days, I had to delete this file. I suspect this has been changed in your config. But as said, all you need to do is zero that axis and it will be remembered for next time.

I'm not sure how it compares with Mach, but Linuxcnc has an extensive coordinate system which is well documented here

linuxcnc.org/docs/devel/html/gcode/coordinates.html.

This is really designed for a situation where you might have seperate fixtures on a machining centre. I knew somebody who had 4 vices mounted to a big ally plate that he installed in his mill sometimes. So Each vice could be set up with a different coordinate system (eg G54, G55, G56, G57)

With Plasma, we only really need one coordinate system so we use G54. So when we touch off with the GUI buttons to set X0 Y0 we can also do it in the MDI window by typing G54 X0 Y0.

Also note the QTplasmac can rotate the coordinate system around the toch to account for a squewed sheet from the GUI. I'll let you explore that feature in the QTplasmac docs

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11737

- Thank you received: 3973

06 Jul 2021 06:48 #213828

by rodw

Replied by rodw on topic New Project with Mesa 7I96 and THCAD-05

So because I have a laser pointer on my system, I don't really care where a job starts. For a full sheet, I will touch off in the front left corner but for one offs, I might just move to a spare spot on the sheet and Zero the work coordinates to the laser crosshairs (which is also supported by QTplasmac).

Truly, getting my head around G54 offsets changed my life! It makes it work so simply!

Truly, getting my head around G54 offsets changed my life! It makes it work so simply!

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

06 Jul 2021 14:04 #213855

by acourtjester

Replied by acourtjester on topic New Project with Mesa 7I96 and THCAD-05

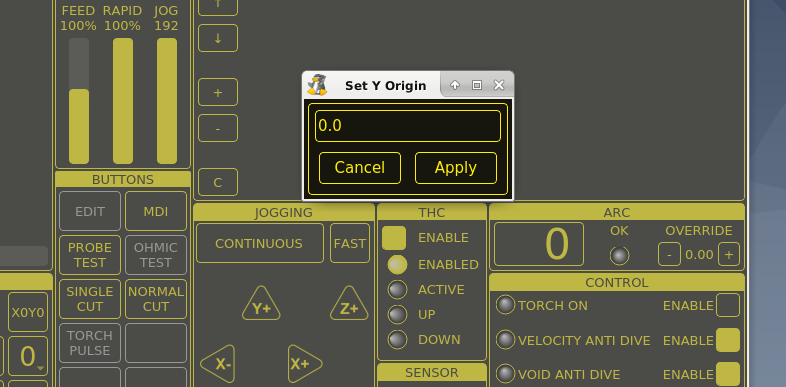

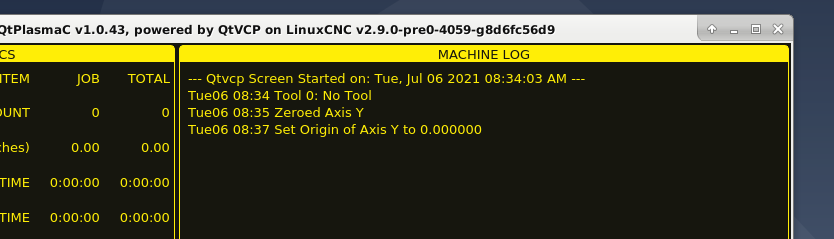

There is a simple solution to the Y 0.0 problem I had, This is why I asked where do I change it.

There is a menu box that pops up when you want to 0.0 the DRO after homing, and other time.

After doing a Home All I clicked on the Y "0" box the menu pops up with 4 selections

Zero

set

divide by 2

set last

I clicked on zero and then set, set brings up a menu box for you to enter what you want the DRO to show.

I entered 0.0 next I ran each axis away from home and did Home All again. This time each home and put 0.0 in it’s DRO

On to the next hickup

There is a menu box that pops up when you want to 0.0 the DRO after homing, and other time.

After doing a Home All I clicked on the Y "0" box the menu pops up with 4 selections

Zero

set

divide by 2

set last

I clicked on zero and then set, set brings up a menu box for you to enter what you want the DRO to show.

I entered 0.0 next I ran each axis away from home and did Home All again. This time each home and put 0.0 in it’s DRO

On to the next hickup

Attachments:

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

06 Jul 2021 14:18 #213857

by acourtjester

Replied by acourtjester on topic New Project with Mesa 7I96 and THCAD-05

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

06 Jul 2021 23:55 #213916

by phillc54

Replied by phillc54 on topic New Project with Mesa 7I96 and THCAD-05

That laser should work well in QtPlasmaC.

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_laser

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_laser

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

07 Jul 2021 00:18 #213920

by acourtjester

Replied by acourtjester on topic New Project with Mesa 7I96 and THCAD-05

Thanks Phill

When I get down the road a little more It will be used. I have a laser already mounted on the Y axis with a toggle switch for power but will change when needed.

When I get down the road a little more It will be used. I have a laser already mounted on the Y axis with a toggle switch for power but will change when needed.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21376

- Thank you received: 7289

07 Jul 2021 00:30 #213924

by tommylight

Replied by tommylight on topic New Project with Mesa 7I96 and THCAD-05

It does, use it daily on 3 machines, soon on 5 just need to find lasers, i am out!That laser should work well in QtPlasmaC.

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_laser

Please Log in or Create an account to join the conversation.

Time to create page: 0.159 seconds