Search Results (Searched for: )

- meister

- meister

20 Jun 2025 15:53

- TheTinkeringMechanic1

- TheTinkeringMechanic1

20 Jun 2025 15:19

Replied by TheTinkeringMechanic1 on topic Reposition Preview grid.

Reposition Preview grid.

Category: Basic Configuration

- Aciera

20 Jun 2025 15:06

Replied by Aciera on topic Reposition Preview grid.

Reposition Preview grid.

Category: Basic Configuration

- AdelRTP

- AdelRTP

20 Jun 2025 15:04

- unknown

- unknown

20 Jun 2025 14:50

Replied by unknown on topic (SOLVED) hal_gpio: Operation not permitted fault cannot be solved

(SOLVED) hal_gpio: Operation not permitted fault cannot be solved

Category: HAL

- unknown

- unknown

20 Jun 2025 14:47

Replied by unknown on topic (SOLVED) hal_gpio: Operation not permitted fault cannot be solved

(SOLVED) hal_gpio: Operation not permitted fault cannot be solved

Category: HAL

- PCW

20 Jun 2025 14:26

Replied by PCW on topic Lo ejes dejaron de moverse

Lo ejes dejaron de moverse

Category: General LinuxCNC Questions

- bladekel

- bladekel

20 Jun 2025 14:15 - 20 Jun 2025 14:19

(SOLVED) hal_gpio: Operation not permitted fault cannot be solved was created by bladekel

(SOLVED) hal_gpio: Operation not permitted fault cannot be solved

Category: HAL

- Sekai

- Sekai

20 Jun 2025 14:03

- TheTinkeringMechanic1

- TheTinkeringMechanic1

20 Jun 2025 13:28

Replied by TheTinkeringMechanic1 on topic Reposition Preview grid.

Reposition Preview grid.

Category: Basic Configuration

- Johnnysacalu

- Johnnysacalu

20 Jun 2025 12:40

Replied by Johnnysacalu on topic Lo ejes dejaron de moverse

Lo ejes dejaron de moverse

Category: General LinuxCNC Questions

- Aciera

20 Jun 2025 12:39

Replied by Aciera on topic Reposition Preview grid.

Reposition Preview grid.

Category: Basic Configuration

- TheTinkeringMechanic1

- TheTinkeringMechanic1

20 Jun 2025 11:57

Replied by TheTinkeringMechanic1 on topic Reposition Preview grid.

Reposition Preview grid.

Category: Basic Configuration

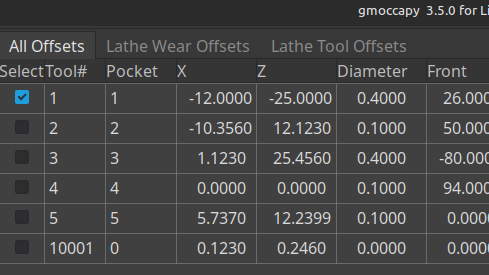

- Aciera

20 Jun 2025 11:49

Replied by Aciera on topic Fanuc-Style Toolchange

Fanuc-Style Toolchange

Category: Advanced Configuration

- knipknap

- knipknap

20 Jun 2025 11:09

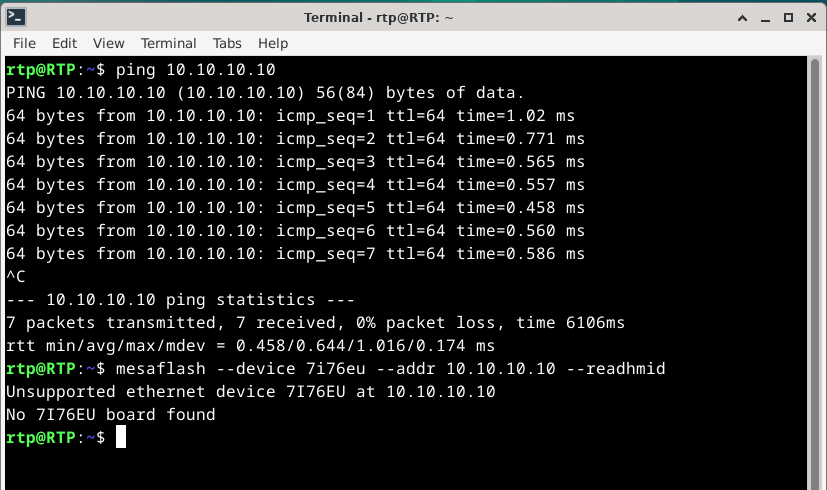

Replied by knipknap on topic MESA 7i76E burning out issue

MESA 7i76E burning out issue

Category: Driver Boards

Time to create page: 0.232 seconds