Search Results (Searched for: )

- rajsekhar

- rajsekhar

13 Oct 2024 12:56

Replied by rajsekhar on topic IRQ Affinity setup

IRQ Affinity setup

Category: Computers and Hardware

- rajsekhar

- rajsekhar

13 Oct 2024 12:55 - 13 Oct 2024 12:58

- BSOD

- BSOD

13 Oct 2024 12:48

- Muecke

13 Oct 2024 12:42

Replied by Muecke on topic Unterstützung bei der Automatisierung einer Simulation

Unterstützung bei der Automatisierung einer Simulation

Category: Deutsch

- jacgri24

- jacgri24

13 Oct 2024 12:41

Control feed speed with a potentiometer was created by jacgri24

Control feed speed with a potentiometer

Category: General LinuxCNC Questions

- Aciera

13 Oct 2024 12:41 - 13 Oct 2024 12:43

- Aciera

13 Oct 2024 12:30

- Aciera

13 Oct 2024 12:14

Replied by Aciera on topic Unterstützung bei der Automatisierung einer Simulation

Unterstützung bei der Automatisierung einer Simulation

Category: Deutsch

- Muecke

13 Oct 2024 12:12 - 13 Oct 2024 12:15

Unterstützung bei der Automatisierung einer Simulation was created by Muecke

Unterstützung bei der Automatisierung einer Simulation

Category: Deutsch

- tommylight

13 Oct 2024 12:09

- tommylight

13 Oct 2024 12:07

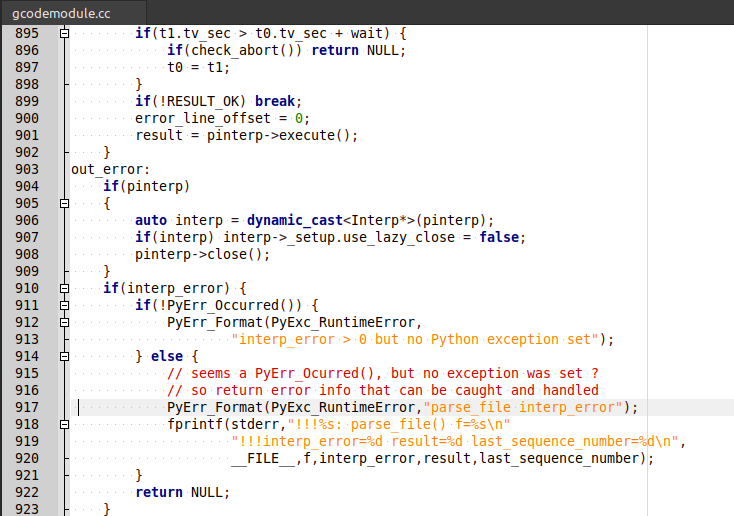

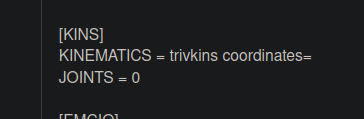

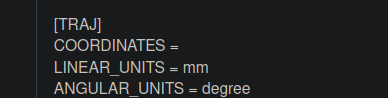

Replied by tommylight on topic Issues with migrating configuration from LCNC 2.8.3 buster to 2.9.3 bookworm

Issues with migrating configuration from LCNC 2.8.3 buster to 2.9.3 bookworm

Category: QtPyVCP

- tommylight

13 Oct 2024 12:03

Replied by tommylight on topic No of I/O pins available on Pi 5

No of I/O pins available on Pi 5

Category: General LinuxCNC Questions

- freemoore

- freemoore

13 Oct 2024 12:01

Replied by freemoore on topic Request for Mesa 5i23_7i48_7i52 firmware

Request for Mesa 5i23_7i48_7i52 firmware

Category: Driver Boards

- tommylight

13 Oct 2024 11:52

Replied by tommylight on topic 3D printed stuff, showcase it here

3D printed stuff, showcase it here

Category: Additive Manufacturing

- tommylight

13 Oct 2024 11:51

Replied by tommylight on topic Adding GUI file to bootable pend drive is this possible

Adding GUI file to bootable pend drive is this possible

Category: Installing LinuxCNC

Time to create page: 0.421 seconds