New Project with Mesa 7I96 and THCAD-05

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

26 Jul 2021 23:42 #215996

by acourtjester

Replied by acourtjester on topic New Project with Mesa 7I96 and THCAD-05

THCAD freq numbers for each

THCAD-10

0 volts == 123.0 K

10 volts – 946.8 K

THCAD -5

0 volts == 138.3 K

5 volts == 966.4 K

THCAD-10

0 volts == 123.0 K

10 volts – 946.8 K

THCAD -5

0 volts == 138.3 K

5 volts == 966.4 K

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11695

- Thank you received: 3945

26 Jul 2021 23:48 - 26 Jul 2021 23:50 #215997

by rodw

Make sure STEPGEN_MAXVEL and STEPGEN_MAXACCEL should be double the values above. ie. for JOINT-0

Replied by rodw on topic New Project with Mesa 7I96 and THCAD-05

Tom, also in your ini fileIf you use PnCconf on an existing config and add an arc voltage enoder it will put the required scale and offset values in a file ending in "new" in the config directory.

I'd rather not confuse Tom at this stage. We can tell him what the values should be.

MAX_VELOCITY = 35

MAX_ACCELERATION = 17

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 44

STEPGEN_MAXACCEL = 22# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 25

STEPGEN_MAXACCEL = 100

Last edit: 26 Jul 2021 23:50 by rodw.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

26 Jul 2021 23:52 #215998

by phillc54

Replied by phillc54 on topic New Project with Mesa 7I96 and THCAD-05

Well I was just saying that the values are already calculated and in a file...

Why double the stegen values when not using backlash compensation, I have never found the need for that.

Why double the stegen values when not using backlash compensation, I have never found the need for that.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11695

- Thank you received: 3945

27 Jul 2021 00:00 #215999

by rodw

This should be correct though

Replied by rodw on topic New Project with Mesa 7I96 and THCAD-05

Yeh, I stuffed up there and the forum makes it too hard to edit.Well I was just saying that the values are already calculated and in a file...

Why double the stegen values when not using backlash compensation, I have never found the need for that.

This should be correct though

MAX_VELOCITY = 35

MAX_ACCELERATION = 17

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 44

STEPGEN_MAXACCEL = 22Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

27 Jul 2021 00:03 #216000

by acourtjester

Replied by acourtjester on topic New Project with Mesa 7I96 and THCAD-05

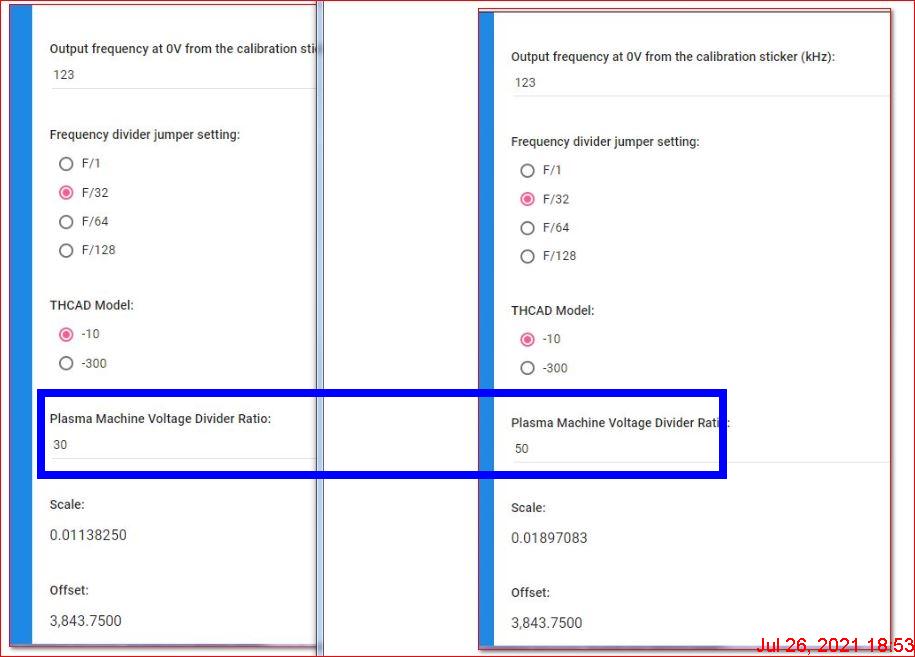

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11695

- Thank you received: 3945

27 Jul 2021 00:10 #216002

by rodw

Replied by rodw on topic New Project with Mesa 7I96 and THCAD-05

You need to whatever is set inside your plasma cutter in the calculator. What is it set at? 20:1 is a good setting if your machine accepts it.

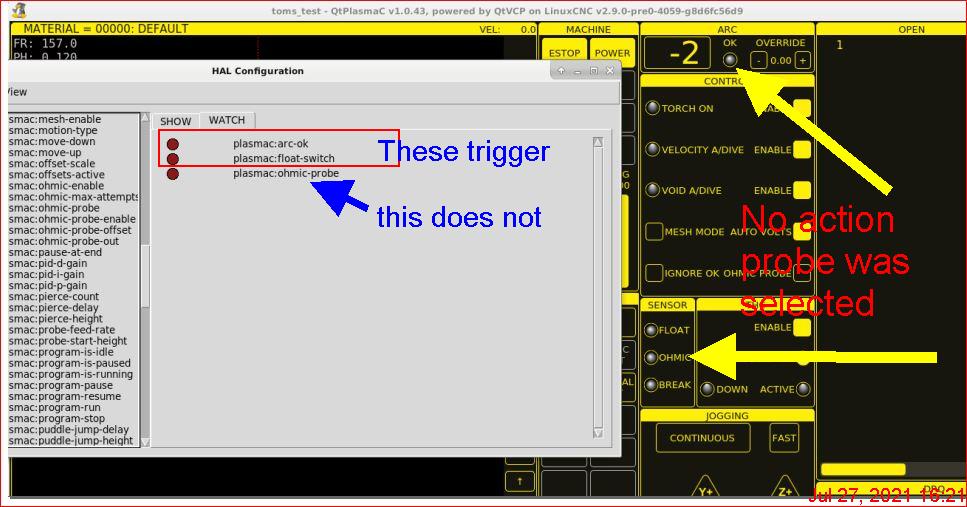

The custom.hal file seems to be set up right right for ohmic sensing

The custom.hal file seems to be set up right right for ohmic sensing

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

27 Jul 2021 00:42 #216003

by acourtjester

Replied by acourtjester on topic New Project with Mesa 7I96 and THCAD-05

Thanks for the files I will use them in the morning, sending the files is a great help as my head is spinning due to my lack of knowledge.

Please Log in or Create an account to join the conversation.

- acourtjester

- Offline

- Elite Member

-

Less

More

- Posts: 292

- Thank you received: 29

27 Jul 2021 21:43 #216070

by acourtjester

Replied by acourtjester on topic New Project with Mesa 7I96 and THCAD-05

Thanks you so much with the files you changed and adding the Arc Voltage offset and scale I now see the voltage registering on the main screen. With the 50 to 1 and a 9 volt battery it showed 450.

Ohmic sensor does not show any action on screen or in Hal show. does it need a offset value to be entered like the arc voltage did??

I read you can copy the SheetCam tools into the LinuxCNC materials files, if true how do I do it. I have the file for the tools I used and it would be nice to just copy them over.

I have said thanks before but I cannot say how much I appreciate the help you have given this rookie with LinuxCNC. I feel I am very close to making sparks with the new table.

I read you can copy the SheetCam tools into the LinuxCNC materials files, if true how do I do it. I have the file for the tools I used and it would be nice to just copy them over.

I have said thanks before but I cannot say how much I appreciate the help you have given this rookie with LinuxCNC. I feel I am very close to making sparks with the new table.

Attachments:

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2533

- Thank you received: 865

27 Jul 2021 23:20 - 27 Jul 2021 23:45 #216078

by snowgoer540

Replied by snowgoer540 on topic New Project with Mesa 7I96 and THCAD-05

You do not have ohmic probe checked on the GUI (I did this same thing myself this evening), so I wouldn’t expect ohmic probe to work at this point  give that box a check and report back.

give that box a check and report back.

Last edit: 27 Jul 2021 23:45 by snowgoer540.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

27 Jul 2021 23:22 #216079

by phillc54

Replied by phillc54 on topic New Project with Mesa 7I96 and THCAD-05

The float switch is connected to:so check that pin with Halshow.

There is an offset for the float switch in the parameter tabe but that is just to get the coerrect height when you do the probe test set up.

linuxcnc.org/docs/devel/html/plasma/qtpl...tml#qt_initial-setup

The material importer is here:

linuxcnc.org/docs/devel/html/plasma/qtpl...#_material_converter

hm2_7i76e.0.7i76.0.0.input-11There is an offset for the float switch in the parameter tabe but that is just to get the coerrect height when you do the probe test set up.

linuxcnc.org/docs/devel/html/plasma/qtpl...tml#qt_initial-setup

The material importer is here:

linuxcnc.org/docs/devel/html/plasma/qtpl...#_material_converter

Please Log in or Create an account to join the conversation.

Time to create page: 0.184 seconds