Search Results (Searched for: )

- rodw

15 Jan 2025 03:00

Replied by rodw on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- cakeslob

- cakeslob

15 Jan 2025 02:47 - 15 Jan 2025 02:51

- notJamesLee

- notJamesLee

15 Jan 2025 02:34 - 15 Jan 2025 02:37

First Start Up - E Stops was created by notJamesLee

First Start Up - E Stops

Category: General LinuxCNC Questions

- Srwils

- Srwils

15 Jan 2025 02:27

Replied by Srwils on topic Chinese Servo Drive Calibration XP200

Chinese Servo Drive Calibration XP200

Category: Milling Machines

- bnet

15 Jan 2025 01:21 - 15 Jan 2025 01:28

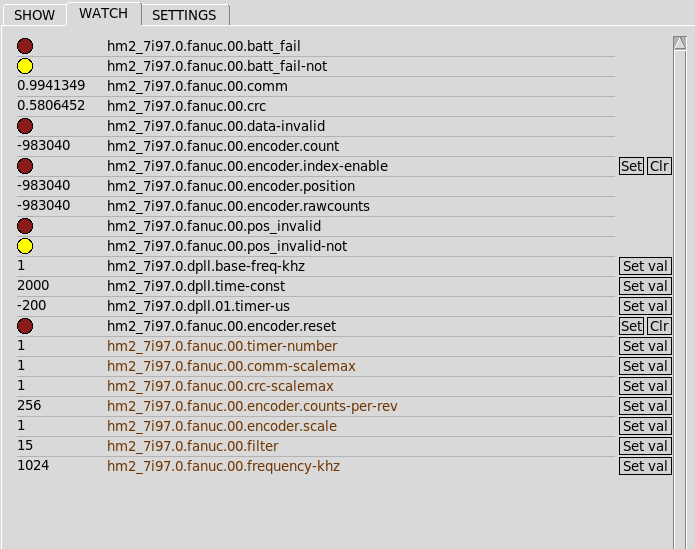

Replied by bnet on topic Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Category: Driver Boards

- PCW

15 Jan 2025 01:04

Replied by PCW on topic Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Category: Driver Boards

- langdons

15 Jan 2025 00:24

Replied by langdons on topic Homing an axis moves away from home switch!

Homing an axis moves away from home switch!

Category: StepConf Wizard

- bnet

14 Jan 2025 23:19

Replied by bnet on topic Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Fanuc Serial Pulse Coders - Red cap servos, mesa 7i76e, how to?

Category: Driver Boards

- Tntmold

- Tntmold

14 Jan 2025 23:04

Replied by Tntmold on topic Lichuan Ethercat Nema23 closed loop stepper motor XML configuration

Lichuan Ethercat Nema23 closed loop stepper motor XML configuration

Category: EtherCAT

- PCW

14 Jan 2025 22:53 - 14 Jan 2025 23:00

- PCW

14 Jan 2025 22:34

Replied by PCW on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

Servo Wiring and Tuning detailed How To example Mesa 7i77.

Category: Advanced Configuration

- vre

- vre

14 Jan 2025 22:10

Replied by vre on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

Servo Wiring and Tuning detailed How To example Mesa 7i77.

Category: Advanced Configuration

- vre

- vre

14 Jan 2025 22:05

- tommylight

14 Jan 2025 21:39

Replied by tommylight on topic Coordinate system in GUI does not match machine

Coordinate system in GUI does not match machine

Category: Basic Configuration

- PCW

14 Jan 2025 21:27

Replied by PCW on topic Maus funktioniert nicht bei Spindel Start

Maus funktioniert nicht bei Spindel Start

Category: Deutsch

Time to create page: 0.361 seconds